Microswiss FlowTech™ Hotend for Bambu Lab X1/X1C - Brass Plated CHT - High Flow

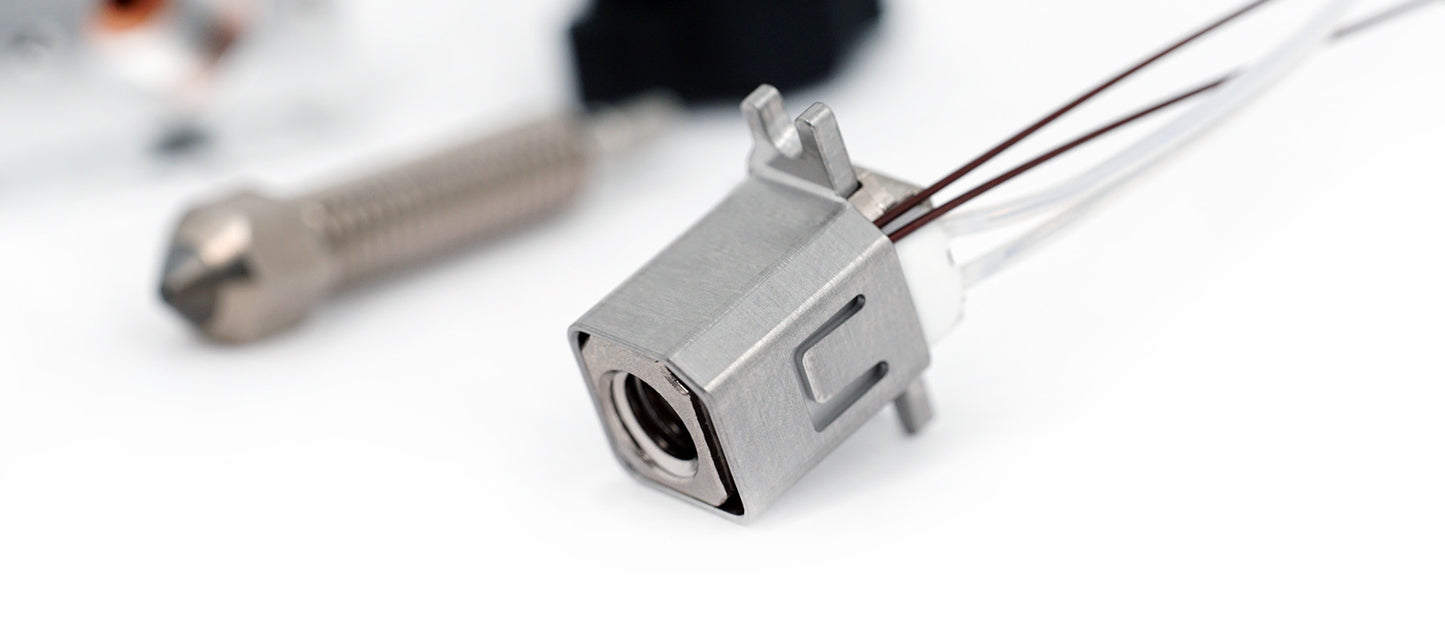

The FlowTech Hotend with Brass-Plated CHT Nozzle is a drop-in, high-flow upgrade for the Bambu Lab X1 and X1 Carbon (X1C) printers. Designed for speed and efficiency, it combines Micro Swiss' FlowTech thermal system with a Core Heating Technology (CHT) nozzle to achieve superior melting rates, reduced back pressure, and smoother extrusion at higher print speeds - without the need for firmware or hardware changes.

Important features

- Compatible with Bambu Lab X1 & X1 Carbon (X1C)

- Brass-plated CHT nozzle for increased melt volume

- Supports high-speed and high-flow printing

- Bimetal thermal barrier for excellent thermal insulation

- Cold replaceable nozzle - no hot tightening required

- Full plug-and-play with standard firmware and AMS

Built for speed and volume

The included brass-plated CHT nozzle features internal core-splitting channels that increase the filament contact area with the heated walls. This dramatically improves melting efficiency, enabling higher extrusion speeds and consistent material flow - even with thicker layers or faster movements.

Precision thermal control

The FlowTech Hotend uses a bimetal heatsink with a copper outer shell and a stainless steel inner core. This design prevents heat creep by creating a sharp thermal boundary, ensuring stable temperatures in the melt zone and reducing the risk of clogging during long or high-speed prints.

Plug-and-Play integration

Designed specifically for the X1 and X1 Carbon series, this hotend fits perfectly into the standard bracket and works seamlessly with the printer's firmware, slicer profiles, and AMS system. No configuration, tuning, or adjustments are required - just install and print.

Cold replaceable nozzle design

FlowTech's innovative nozzle interface allows you to change nozzles at room temperature without the use of tools or heating, saving time and eliminating the risk of overvoltage or thermal damage during maintenance.