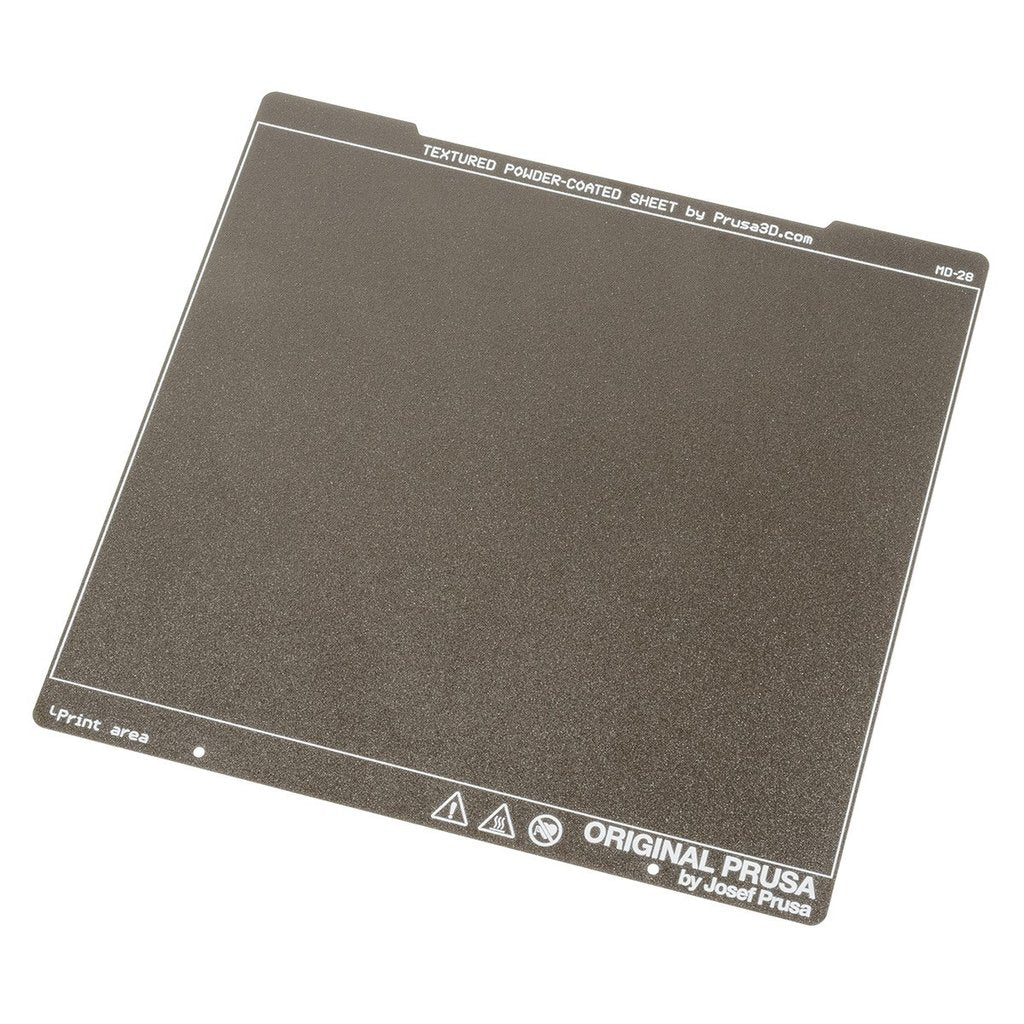

Textured Powder-coated

The MK52 heatbed has embedded magnets with high Curie temperature. These magnets are capable of holding removable spring steel plates.

Powder coating directly onto metal makes it very difficult to damage this build plate. If a heated nozzle crashed into it, the metal can dissipate the heat. Powder coating also gives the surface a distinct textured look that will be visible on your prints. The textured surface hides most of the mechanical damage caused by tools. Only the top of the small bumps can be scratched, which will not mark the bottom of the model. This surface is used on our print farm, look at the printed parts you have on your printer for reference.

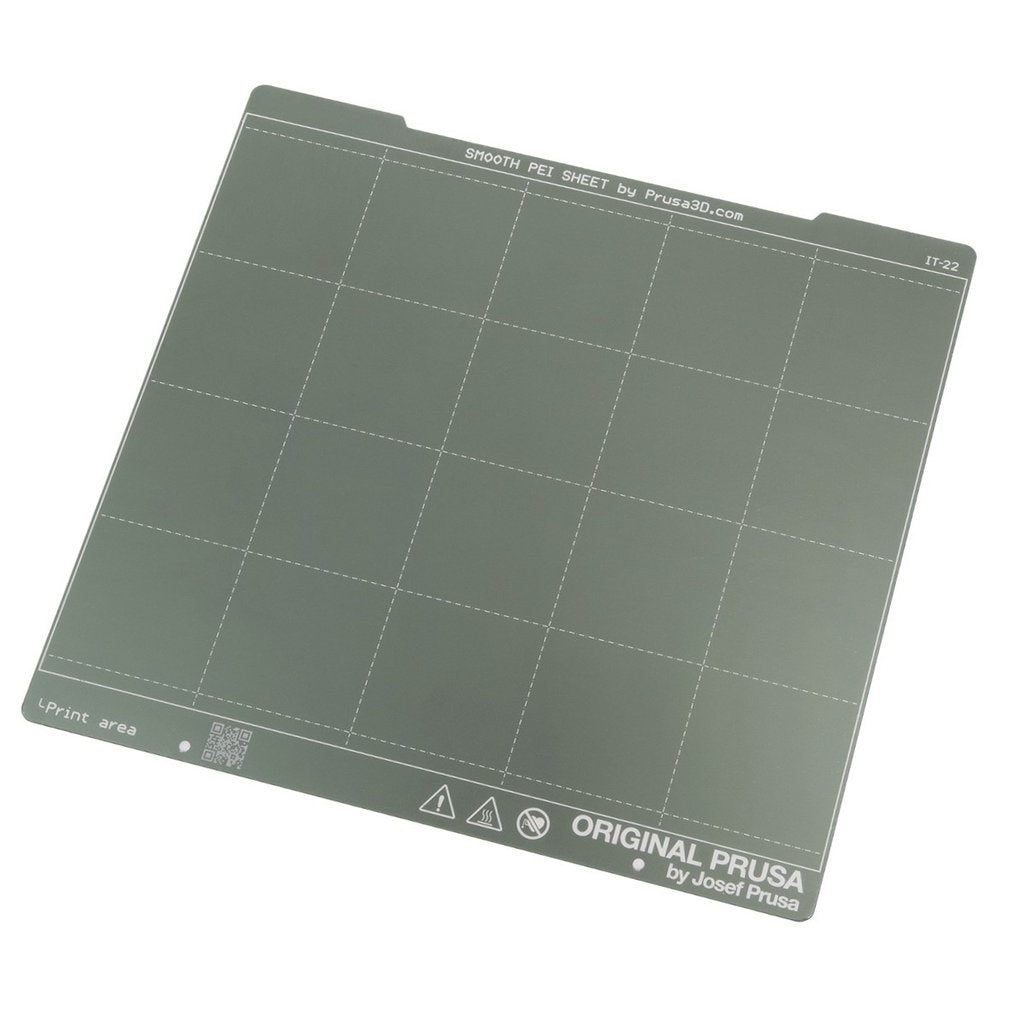

Smooth PEI

The MK52 heatbed has embedded magnets with high Curie temperature. These magnets are able to hold removable spring steel plates. The spring steel plate with smooth double-sided PEI uses the same PEI plates as on the MK2/S. It is the best solution for printing PLA and has good adhesion with almost all materials. The bottom of your prints will be smooth.

You may leave small marks on the print surface with your nozzle or tool, they will typically be glossier than the rest. This does not affect functionality or adhesion. However, if you want the same surface appearance across the entire print bed, you can rebuild it. The easiest way is to take the hard side of a dry kitchen sponge and wipe the affected area with a circular motion gently a few times.

Find more details about the spring steel plates in our knowledge base.

Update:

The steel plate color may differ from the product image (black, gold, green, etc.). The smooth PEI surface of the steel plate, as well as all other properties, remain the same for all color versions.

Satin Powder Coated

The MK52 heatbed has embedded high Curie temperature magnets. These magnets are able to firmly hold removable spring steel sheets.

The Satin sheet further expands our line-up of print sheets. In terms of printing properties, the Satin sheet sits between the smooth and textured variants. Its powder-coated surface with lightly textured matte finish offers an optimal level of adhesion, especially when printing PLA and PETG materials. It is fully compatible with a wide range of common and less-common filaments, such as ABS, ASA, FlexFill 98A, Polycarbonate and more. A vast majority of materials can be printed without a separation layer (eg glue).

Polycarbonate - prints better on satin (compared to smooth and textured sheets) - when printing with PC often, glue stick layer is recommended to prevent possible damage to the sheet.

PA Nylon Powder-coated

The MK52 heatbed has embedded magnets with high Curie temperature. These magnets are capable of holding removable spring steel plates.

This print sheet is specifically designed for printing polyamide based filaments, especially Prusament PA11 Carbon Fiber Black. PA11 type materials generally have lower adhesion on textured or satin printed sheets. This sheet has a special surface finish that increases adhesion and is perfect for Prusament PA11.

You can learn more about the double-sided powder coated PA Nylon spring steel sheet in our knowledge base.

IMPORTANT!

IMPORTANT!

The surface of this sheet should only be cleaned with clean water. Using common agents such as IPA or acetone will lead to rapid deterioration of the surface. Using a glue stick is no longer necessary and is recommended. To clean grease-covered areas, use clean water with a drop of dishwashing liquid.

Note:

Consumable parts such as PEI sheets (smooth, textured, nylon, etc.) are not covered by the warranty as the coatings are designed to wear off over time unless failure has occurred due to a defect in materials or workmanship. Cosmetic damage including but not limited to scratches, dents, cracks or other cosmetic damage is also not covered by the warranty. Only sheets that are defective upon arrival are covered by the warranty.

Due to the temperatures the plate is exposed to during printing, its surface will gradually become glossier or may develop small, matte areas. This visual change does not adversely affect the printing properties and is not considered a cause for a warranty claim.

Please note that with the original Prusa MK4, the wear of PA Nylon plates is particularly noticeable at the Z-probe points where the nozzle leaves visible marks on the surface. This does not affect the surface adhesion and overall printability. You can research the grades in our knowledge base article.