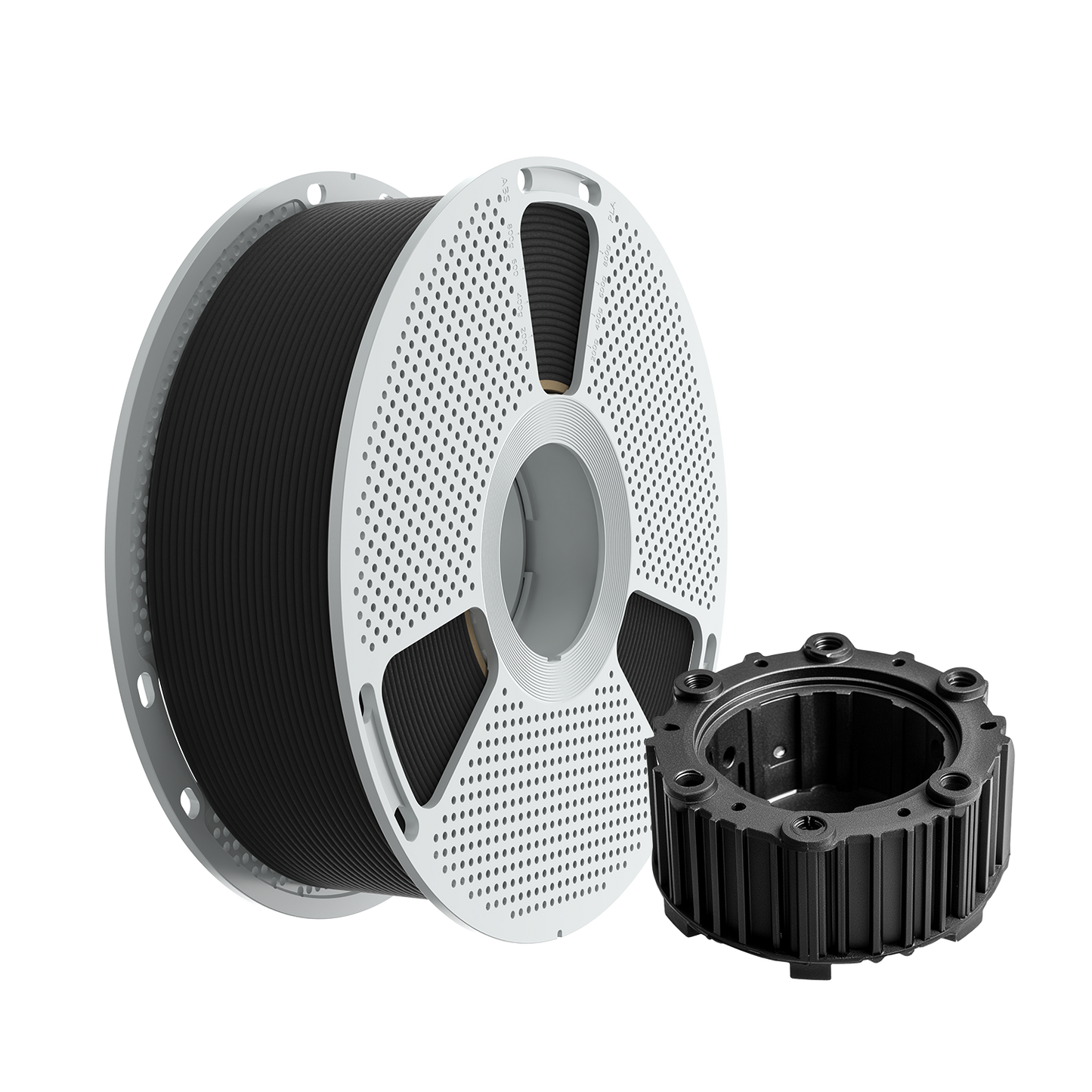

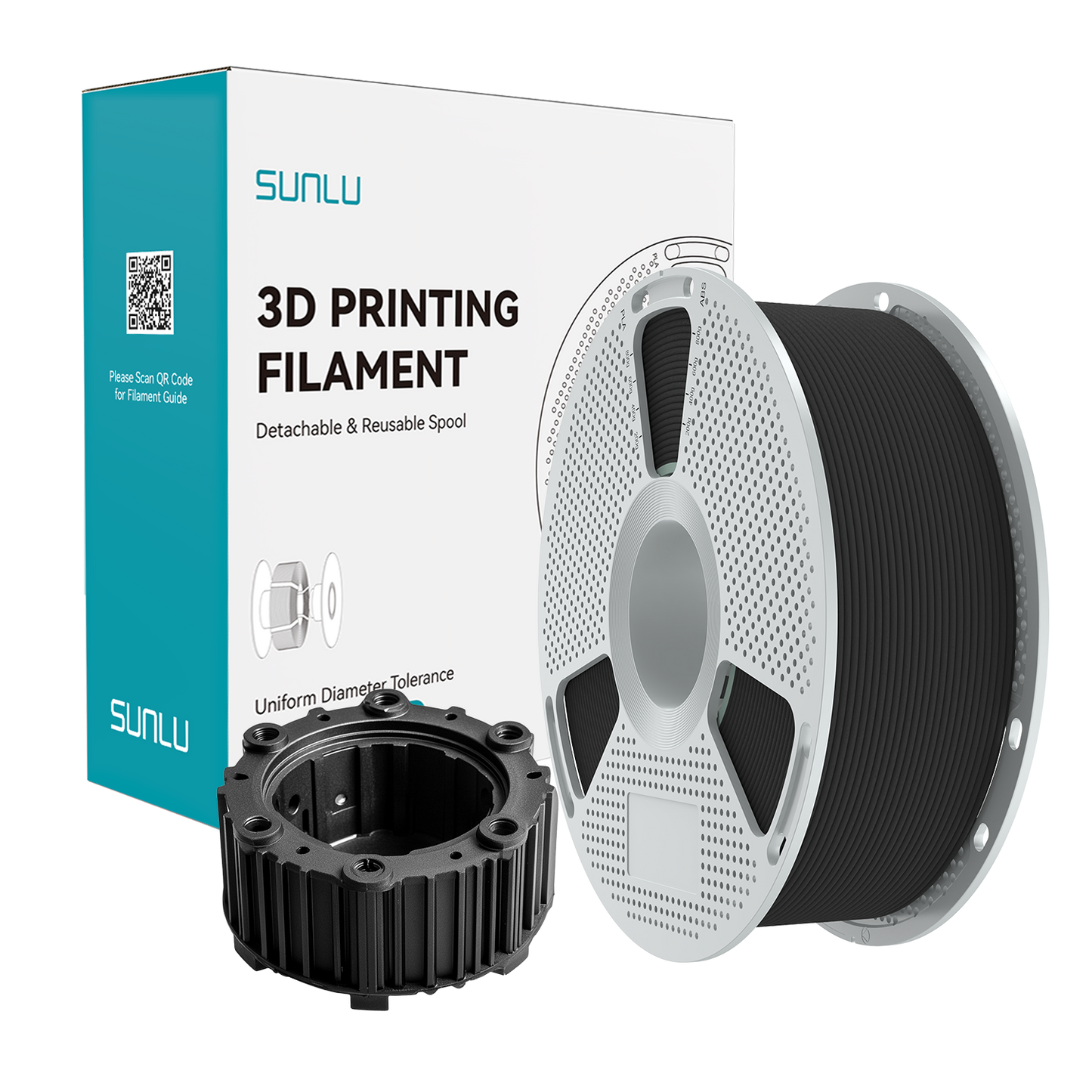

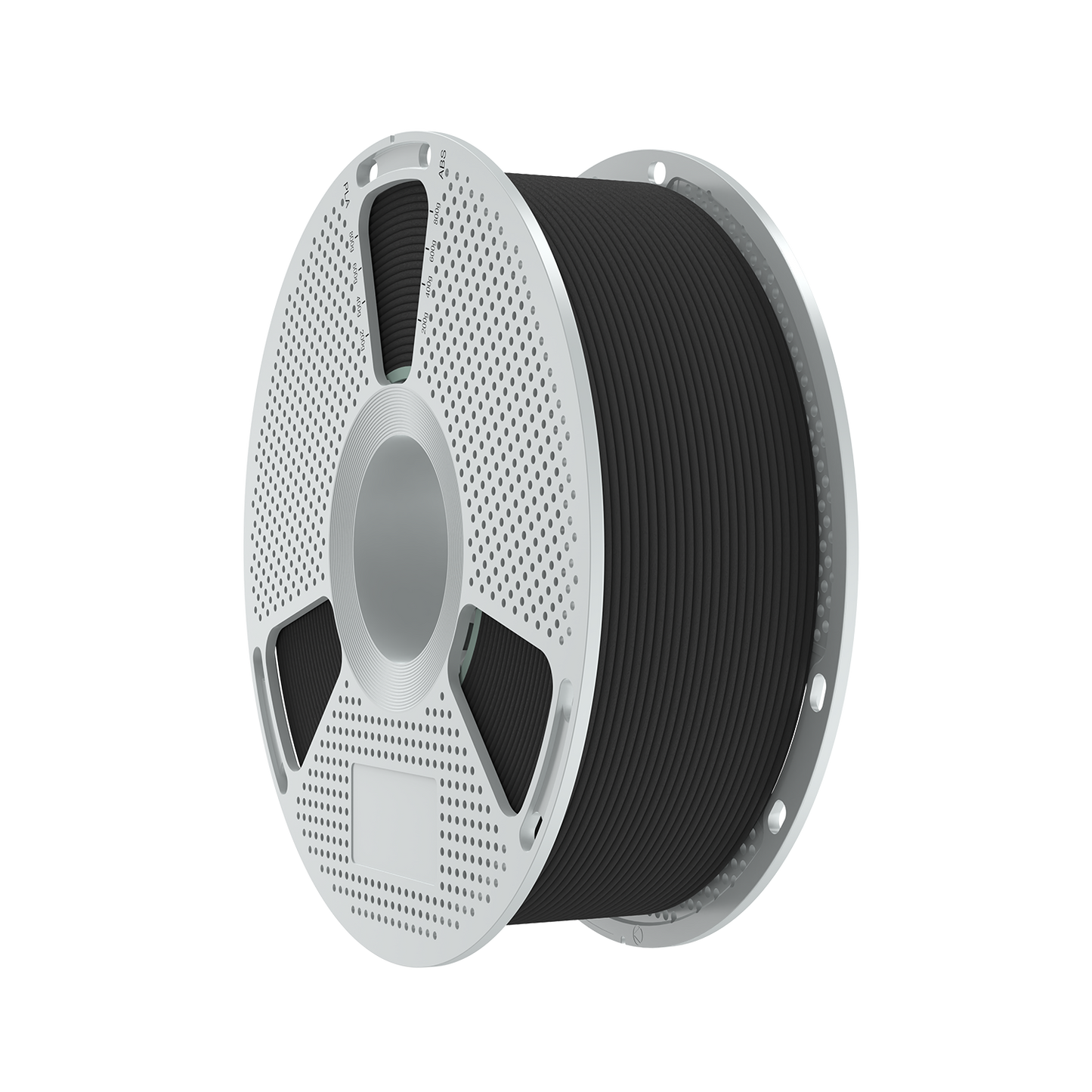

Sunlu Nylon 12 Carbon Fiber - PA12-CF 1.75mm 1 kg

Advanced high temperature resistance

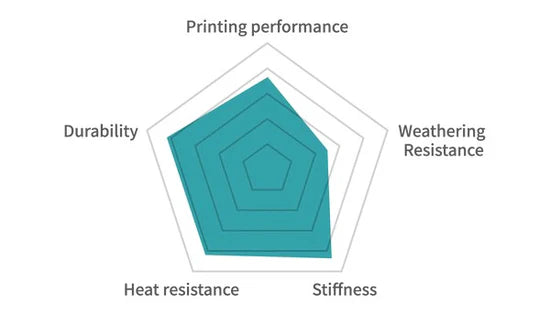

SUNLU PA12-CF is reinforced with carbon fiber and designed to withstand temperatures up to 176°C , ensuring stable performance in demanding environments such as automotive and aerospace. Optimized for printing at 260–280°C and with 50–70°C heated print bed (use glue for better adhesion), making it reliable even under extreme thermal stress.

Lightweight strength for precision design

With reduced density, PA12-CF offers high strength-to-weight ratio , making it ideal for lightweight yet strong components. Perfect for aerospace frames, automotive parts and outdoor equipment where low weight and high durability are essential.

Unparalleled wear resistance and durability

The carbon-reinforced material provides excellent resistance to scratches, abrasion and repeated loading, making it ideal for functional prototypes, industrial tools and long-life mechanical parts.

Excellent shock resistance for demanding use

PA12-CF absorbs shock and resists cracking from drops or collisions. Suitable for rugged outdoor components, drone parts and structural elements that must withstand harsh conditions without losing their strength.

Low moisture absorption and high dimensional stability

With minimal moisture absorption, PA12-CF ensures consistent print quality and precision , without warping or layer shifting. Achieve sharp details and tight tolerances – ideal for gears, aircraft fittings and advanced functional prototypes.

Ideal for: Lightweight automotive and aerospace frames, heavy-duty outdoor equipment, industrial tools and precision components.

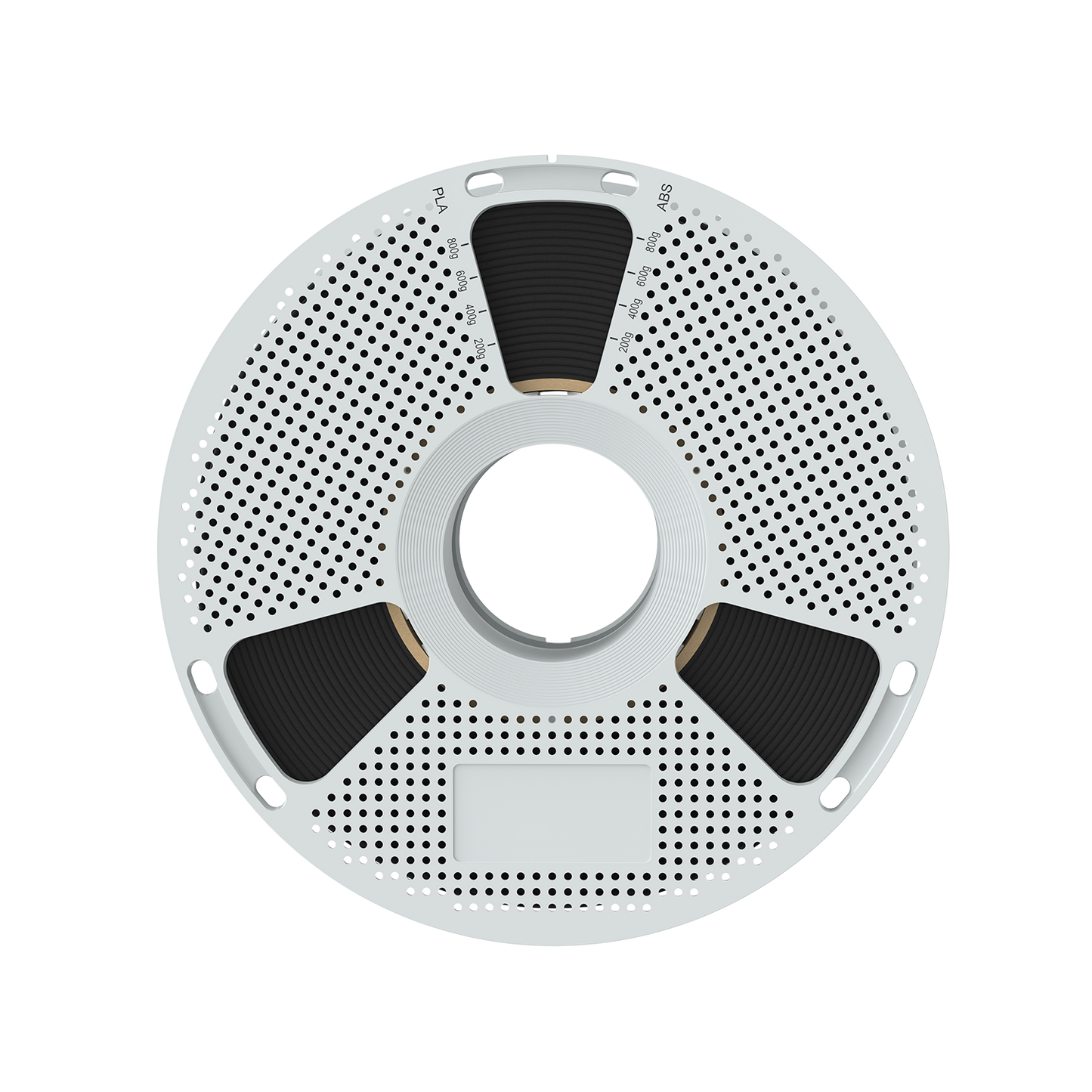

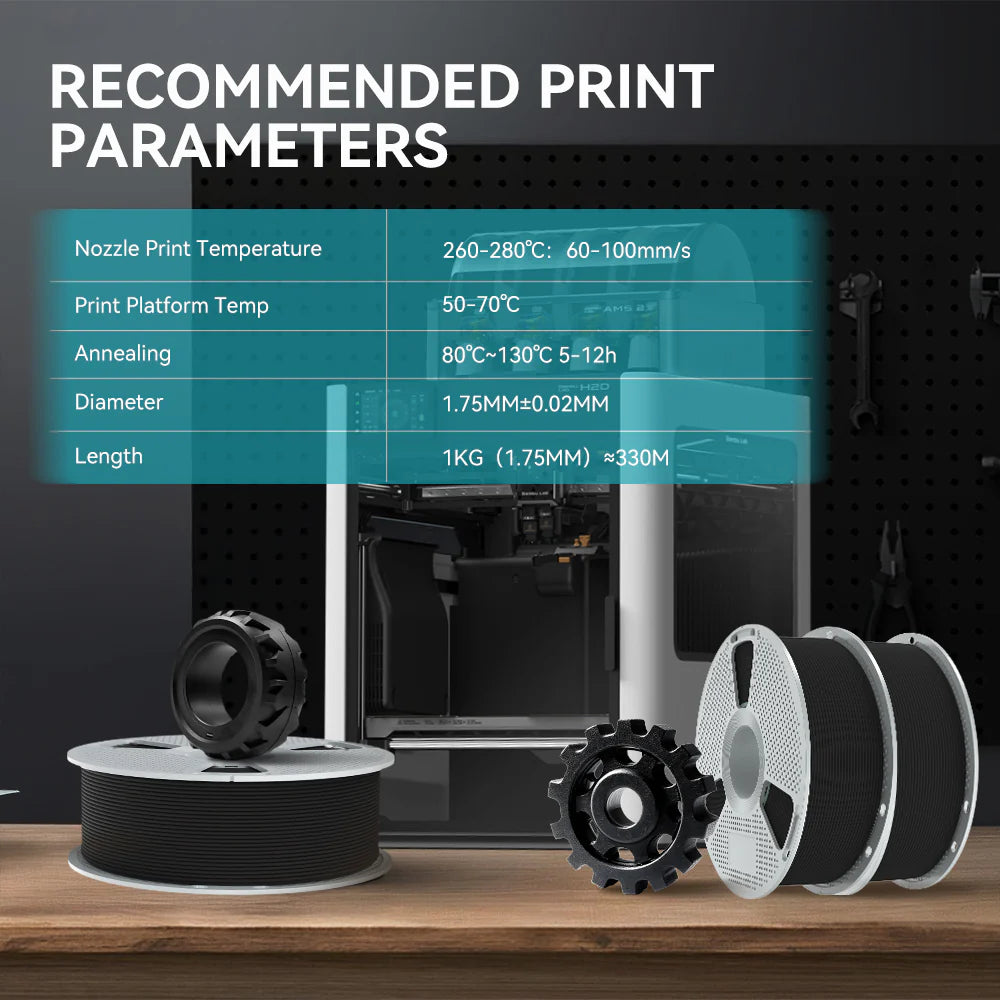

Recommended print settings:

-

Nozzle temperature: 260–280 °C

-

Print bed temperature: 50–70 °C

-

Print speed: 60–100 mm/s

Printing tips for PA12-CF (Nylon 12 with carbon fiber)

-

Low moisture absorption – but still requires drying:

Nylon 12 has the lowest moisture absorption among nylon filaments, but is still more sensitive to moisture than other materials. Therefore, always store the filament dry – ideally at a relative humidity below 20% . -

Drying before use:

After 6 hours of exposure to air , the filament should be dried before printing.

Recommended drying settings:

– 80 °C for 12 hours or

– 110 °C for 4 hours -

Prevent warping:

Use glue stick or special adhesive (e.g. Magigoo PA) on the build plate to improve adhesion and avoid warping. -

Cooling:

Activate the fan at 70% unless your model requires minimal cooling. -

Use durable nozzle:

PA12-CF contains carbon fiber, which wears out faster than standard brass or copper nozzles .

We recommend using a hardened steel nozzle or other durable nozzle type for longer service life.

Post-Processing of models

-

Increase strength through hardening (annealing):

The mechanical properties of the print can be improved by curing in an oven at 80–130 °C for 3–12 hours , depending on the needs and material type. -

Important:

The effect of curing depends on the geometry of the model, its size , and the temperature and time settings used.

Note: Some models may experience warping or deformation during curing, so test with non-critical items first.

PA12-CF – Lightweight strength for demanding applications

PA12-CF combines low weight with high strength and is ideal for the construction of lightweight yet robust components. Perfect for applications such as airframes, automotive components or outdoor equipment where both strength and low mass are essential.

Shockproof and impact-resistant

The material absorbs shock and resists cracking – even from sudden drops or collisions. Suitable for harsh environments and applications such as drone parts, outdoor equipment and load-bearing structures where durability is essential.

Extreme wear resistance and long service life

The embedded carbon fiber structure provides excellent resistance to scratches, abrasion, and repetitive stress, making PA12-CF an excellent choice for functional prototypes, industrial tools, and mechanical parts where long-lasting performance is required.