SUNLU FilaDryer E2 New in 2025 – developed for engineering materials

Dry and glow your filaments in one unit – designed for maximum creative freedom and performance.

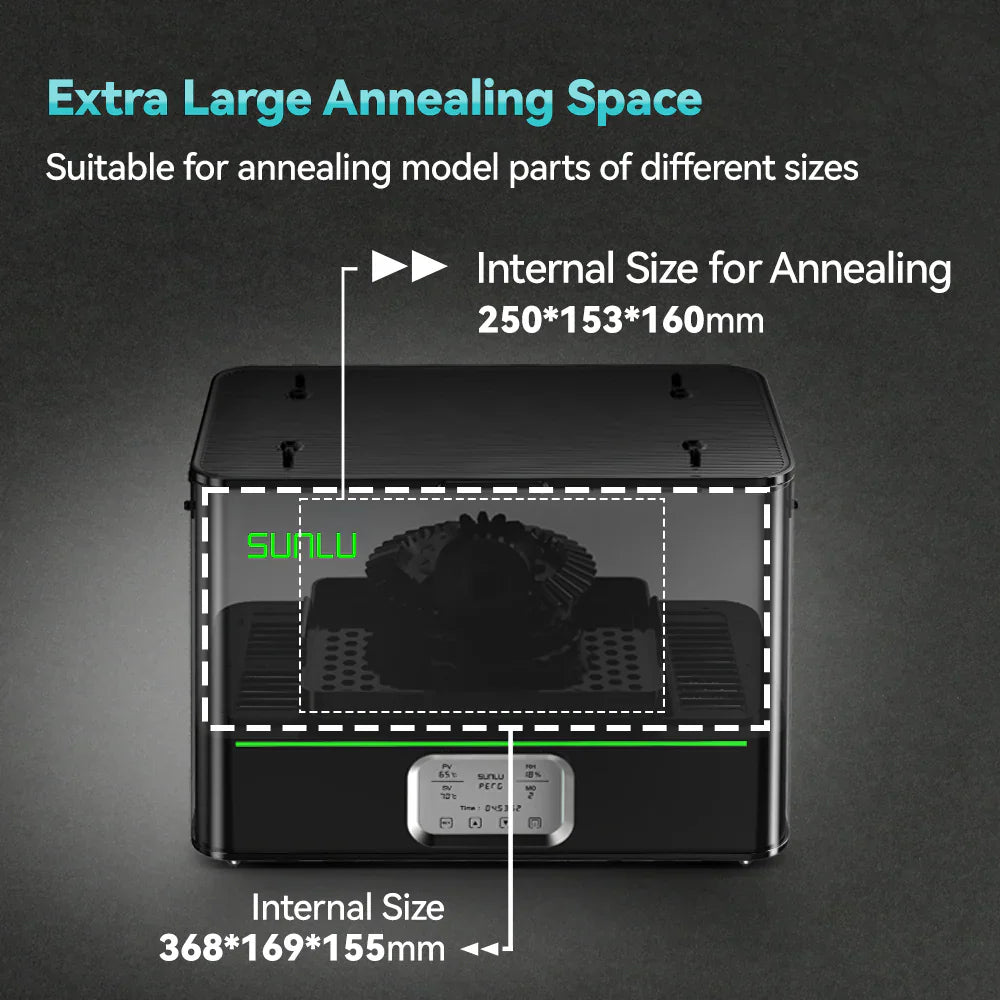

Efficient and advanced annealing

With temperatures up to 110°C, E2 can anneal 99.99% of engineering materials on the market, bringing out the full potential of the materials. The result is models with excellent impact strength and toughness.

Suitable for: ABS, ABS-CF, ASA, PC, flame retardant PC, PC-ABS, PC-PBT, CoPA, PA6-GF, PA6-CF, PA12-CF, PA612-CF, PA12 and others.

What is Annealing and Why is it Important?

Annealing is a heat treatment process in which plastic parts are heated in a controlled environment – typically in a hot air circulation oven or a heated liquid medium – for a specified period of time and then slowly cooled to room temperature.

The purpose is to accelerate the relaxation of the plastic's macromolecular chains and thus remove or reduce the internal stresses that occur during cooling and solidification after printing or molding.

These stresses can cause warping, cracking or deformation over time, especially in precision-requiring or loaded items.

By removing local stress concentrations that occur during uneven cooling, annealing improves the dimensional stability, mechanical strength, and durability of the finished print.

Why It's Especially Important for Engineering Materials

Materials like PA12-CF, PC-ABS, ASA or carbon/glass fiber reinforced filaments are designed for high performance – but for that very reason they are also more sensitive to internal stresses. Without proper annealing, you risk otherwise strong prints losing their function or deforming under load.

SUNLU FilaDryer E2 – Professional Drying and Annealing in One

SUNLU FilaDryer E2 is more than just a drying box – it is a professional 2-in-1 solution for both drying and annealing , specially developed to unleash the full potential of technical and engineering materials .

With temperatures up to 110°C , excellent insulation and dual heating zones, it ensures that your materials are not only dry – but also optimized for maximum strength, durability and precision .

How to Anneal

-

Choose the right temperature

Find the recommended annealing temperature based on the material you are using. -

Check the heating rate

Make sure the model is heated evenly to avoid deformation. -

Maintain a stable temperature

Adjust the duration depending on the size of the model and the material used. -

Check the cooling

Let the model cool down slowly or use controlled cooling for best results.

Tips for successful annealing

-

Precise temperature control is essential – avoid overheating.

-

Make test prints on a smaller scale to minimize errors and material waste.

-

Expect some shrinkage – adjust your design to account for this.

Fast and efficient drying

With a 500W PTC heating element, the device achieves:

-

50°C in just 20 minutes

-

70°C in 30 minutes

(Max. 110°C – note the heat resistance of the coil material)

Excellent tightness and insulation

Tight-fitting silicone plug at the filament outlet and silicone gasket in the lid.

The fully sealed and multi-layered heating chamber effectively insulates and maintains the temperature above 100°C, ensuring optimal annealing and drying.

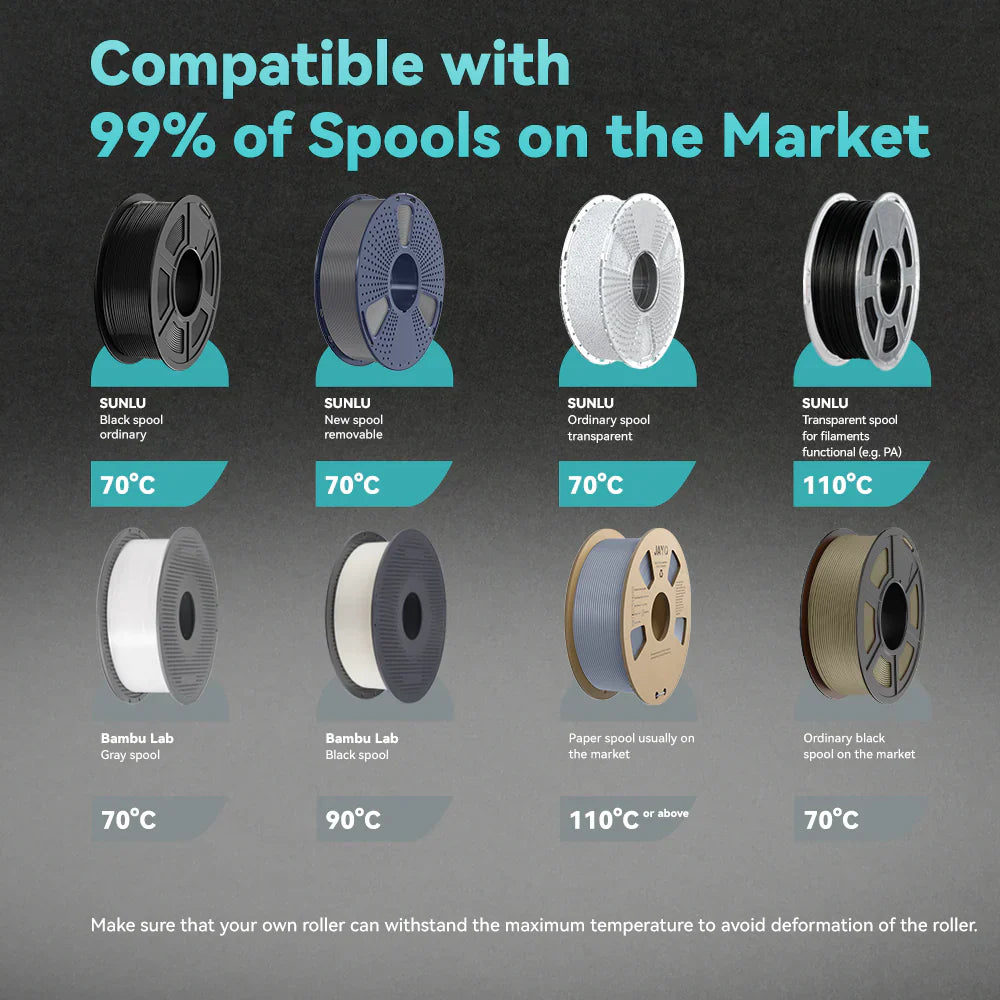

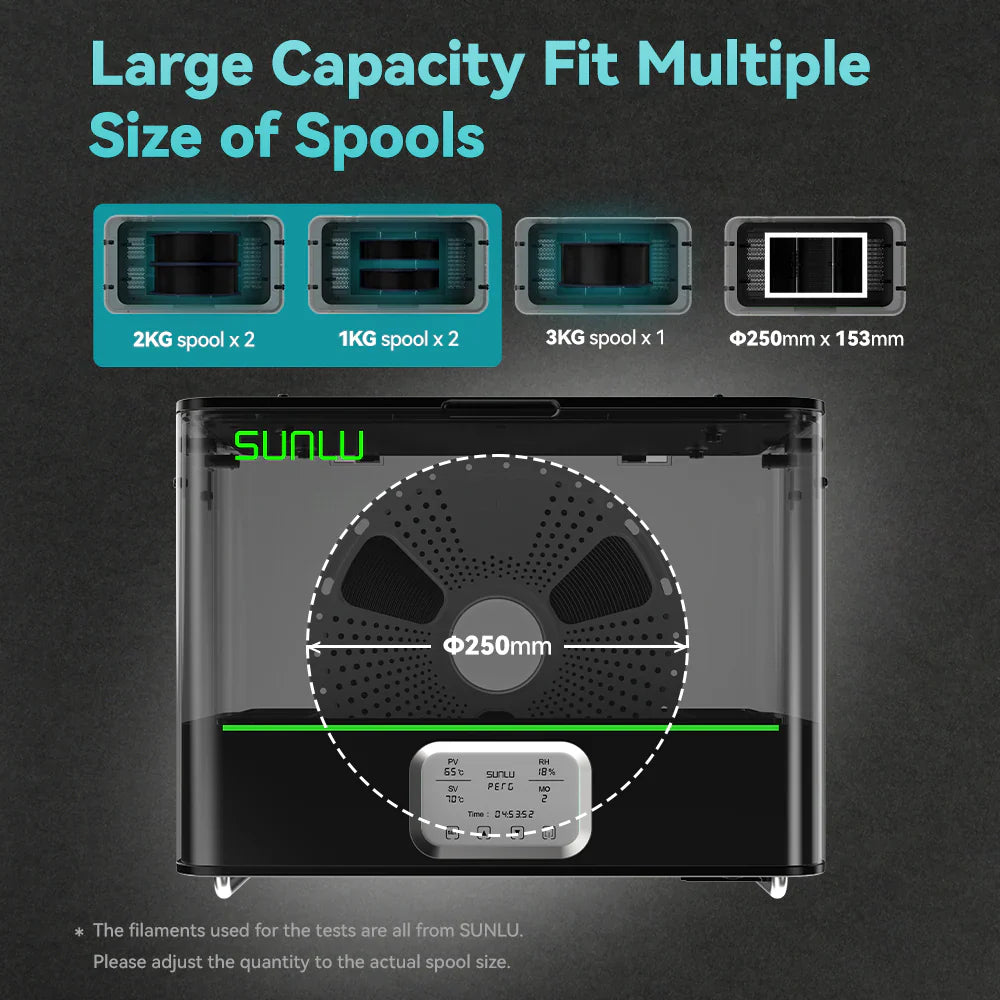

Extra large capacity and high compatibility

Compatible coil capacity (example: SUNLU coils):

-

2 pcs. 1KG

-

2 pcs. 2KG

-

1 piece 3KG

Max. coil size: Ø250mm x 153mm

(Sizes may vary when using other brands – check before use)

Broad compatibility – 99% of usage scenarios

Compatible with both standard and technical filaments.

Supported filament diameters: 1.75mm / 2.85mm / 3.0mm

Included PTFE tubes: 2 pcs. of 8 cm and 2 pcs. á 1m (Ø4x3mm)

Built-in material presets – one click for optimal configuration.

Top-class security

-

Two-stage temperature protection: Automatically switches off when overheating

-

Low external heat: < 60°C even with internal > 100°C

-

Fire retardant materials

-

Standby consumption: ≤1W

Unleash the potential of materials

Annealing improves strength and impact resistance, making your prints suitable for functional parts and advanced applications such as:

-

Drone parts

-

Helmets

-

Screws and nuts

-

Blower pipe

-

Durable, high-load components

Fully Sealed Protection

Excellent air tightness and effective thermal insulation. A one-piece silicone plug covers the wiring hole and ensures maximum sealing.

Prevents Re-absorbing Moisture

The lid is equipped with tight-fitting silicone strips, which effectively prevent water vapor from the outside from entering the chamber.

Effective Heat and Moisture Insulation

The fully enclosed dual chamber design — top, middle and bottom — enables temperatures in excess of 100°C. Combined with the innovative closure system, it provides an optimal annealing process and solves the need for both drying and annealing in one unit.

Security – No Worries

The intelligent protection system will sound an alarm if the temperature exceeds the preset value by 10°C or if the machine operates abnormally.

Automatic temperature control: In case of overheating, the heating is interrupted and cooling is automatically activated.

Double-layer thermal insulation: When the internal temperature exceeds 100°C, the outside remains below 60°C – safe to touch.

Fire-retardant quality materials ensure full protection of both the machine and the user's safety.

More Durable FilaDryer

The internal components have been newly optimized and upgraded to significantly extend the machine's lifespan.

New cooling fan on the motherboard with metal ball bearings improves heat resistance.

The new cover effectively prevents foreign objects from falling down and damaging the air ducts.

Large capacity to fit multiple filament spools

Technical specifications

| Property | Value |

|---|---|

| Product name / Model | FilaDryer E2 |

| Product dimensions | 400 × 220 × 307 mm (L×W×H) |

| Internal dimensions | 372 × 192 × 255mm |

| Package dimensions | 454 × 276 × 362mm |

| Net weight / Gross weight | 6.1KG / 7KG |

| Working temperature | 10°C – 35°C |

| Relative humidity | ≤ 95% |

| Temperature range | 35°C – 110°C |

| Humidity display | 10% – 90% (accuracy ±10%) |

| Hours | 0–99 hours |

| Max power consumption | 2.2A @230V / 4.2A @120V |

Note:

At temperatures ≥80°C, a protection function in the humidity sensor (<10% reading) is activated. The sensor recovers after approx. 20 hours at ≤70°C.

Unboxing video with Sunlu Filadryer E2